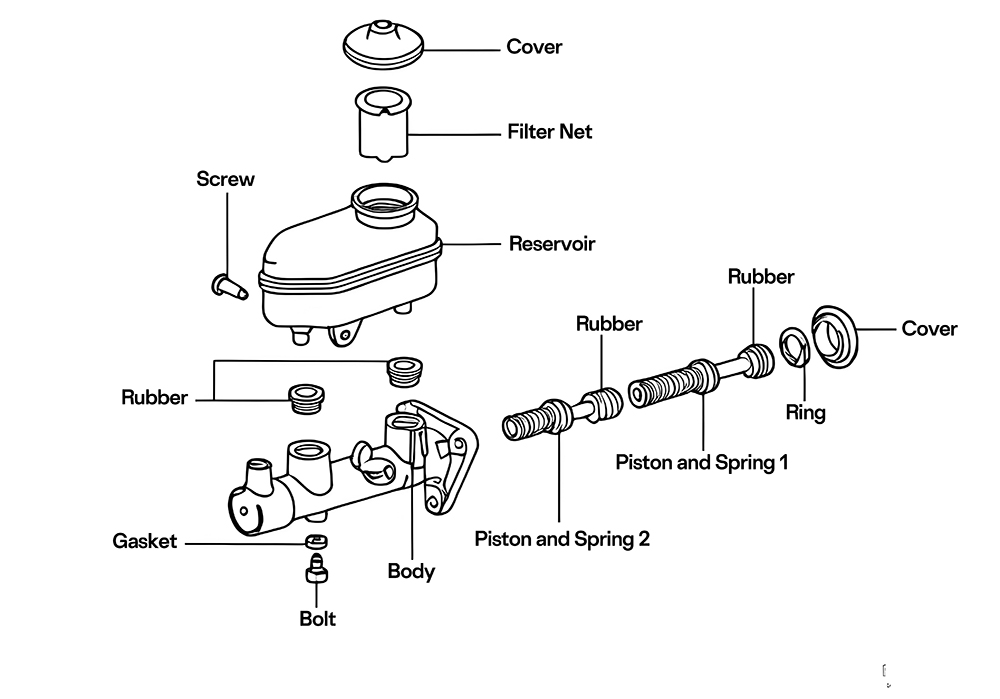

What Are the Components of a Brake Master Cylinder?

Here are the main parts that form a typical brake master cylinder:

Fluid Reservoir – Stores the brake fluid that supplies the master cylinder.

Reservoir Cover – This seals the top of the fluid reservoir, preventing contamination and fluid evaporation.

Filter Net – Positioned under the cover, it keeps dirt and debris from entering the hydraulic system.

Positioning Screw – Ensures precise alignment of internal parts during operation.

Rubber and Gasket – These components prevent leakage and maintain airtight seals within the cylinder.

Catch Bolt – Holds parts of the master cylinder assembly securely in place.

Piston and Spring 1 & 2 – Two piston-spring assemblies allow for dual-circuit operation, providing increased safety in the event of one circuit failing.

Retainer Ring – Keeps internal parts secured inside the cylinder bore.

Anti-Dust Cover – Protects the internal mechanism from dust and debris, extending the service life of the unit.

Each part plays a crucial role in ensuring smooth and responsive braking. A high-quality brake master pump relies on the precise engineering of these components to deliver safe, consistent braking performance.

When choosing a brake master cylinder supplier, quality should always be the top priority. KOMP is a trusted manufacturer specializing in the production of brake master cylinders, brake slave cylinders, clutch master cylinders, and clutch slave cylinders. With a reputation built on precision and durability, KOMP ensures every component meets high-performance standards.

For buyers seeking both reliability and value, KOMP offers factory price brake master cylinder that balance affordability with professional-grade quality. This makes them a preferred choice for automotive professionals, wholesalers, and repair shops around the world.